Dawn of the diesel era

Changes in production had started to occur in 1926 when the Vulcan Foundry began to build diesel-electric locomotives by agreement with A/S Frichs of Aarhus, Denmark, who had been manufacturing diesel engines since 1910. The engines were of the single-acting, four-stroke type with rating from 178 – 1570 b.h.p. at 580 – 875 r/min. and mounted on a solid cast-steel bed to which the fluid feed coupling and main gearbox were also attached. The underbed that formed the engine sump also carried the main crankshaft bearings. As a start, a prototype 0-6-0 shunting locomotive was designed and this was completed in 1935; subsequently 10 rail coaches for New Zealand were manufactured. All these vehicles were provided with Frichs type power units manufactured at the Vulcan Works.

Meanwhile, Davy, Paxman and Co Ltd., Colchester; produced their first diesel engine and in 1929 they installed an eight-cylinder engine for Baisingstoke Urban District Council. This was the first Buchi pressure-charged diesel engine to be put into work commercially on any land installation in the British Isles.

In 1931 Vulcan started production of the mechanical parts for thirty-one heavy freight locomotives that were being built by Metropolitan Vickers Electrical Co for the Great Indian Peninsular Railway; also in the same year Willans & Robinson introduced their ‘H’ series engine, followed by their ‘L’ series of engines which remained in production until 1965. In 1935 Paxman introduced a multi-cylinder vee-form diesel engine.

1932 saw the dawn of a new era, with the first diesel locomotive to be built at the Vulcan Foundry. The design work had been commenced in 1930 and was for a diesel-mechanical 0-6-0 locomotive powered by a six-cylinder Vulcan Frichs diesel engine that produced 274 b.h.p. at 775 r/min. The locomotive entered service with the LMS Railway, but during the war it was taken over by the Ministry of Supply and utilised for hauling traffic on the Melbourne Military Railway.

Collaboration with English Electric

In 1934 English Electric supplied its first ‘K’ engine for use in rail traction applications, this was for a diesel electric shunting locomotive which was to be operated by the LMS Railway. Design work had been started at the Willans Works, Rugby, in 1930. The success of this locomotive inaugurated the dieselisation of the British shunting yards for which more than 1,200 such shunters were to be built over the next twenty-seven years. The ‘K’ range was introduced into service in 1935 for a wide range of duties, although in in-line form only, and with a power output of 50 b.h.p. per cylinder. Its first marine application was in the Clyde ferry Talisman.

Having first started with design work on diesel locomotives in 1932, by 1936 the Vulcan Works began building the mechanical parts for electric and diesel-electric locomotives in conjunction with the English Electric Co Ltd.

Ten diesel mechanical rail coaches were designed and built by the Vulcan Foundry in 1940 for the New Zealand Government Railway. Each was powered by a Vulcan Frichs six-cylinder diesel engine that produced 250 b.h.p. at 1000 r/min.

In 1940 the first supercharged version of the ‘K’ engine was produced and it brought the output per cylinder to 82 b.h.p. During this year Vulcan’s agreement with A/S Frichs ended, because of the hostilities, and a new agreement was entered into with the Dury Car Company Ltd. of America. This agreement was for the manufacture of diesel-mechanical locomotives of under 250 b.h.p. Many locomotives of 153 b.h.p. were built for the Ministry of Supply and Works during the war to be used for industrial and shunting purposes. So popular became this unit for this type of work that it was supplied in four different gauges. In addition, a more powerful version with a 204 b.h.p. engine was made available and was also built in a variety of gauges. The locomotives were provided with the well-known Gardner diesel engine and the Self Changing Gear Co. transmission.

Meanwhile, away from Vulcan, Ruston & Hornsby Limited took over Davy Paxman and Co. (Colchester) Ltd, taking on a company which had been highly successful in developing a range of compact vee-form diesel engines for some years.

In 1942 Vulcan started production of the 2-8-0 renowned Austerity type steam locomotive for the War Department and during 1944 Vulcan Foundry acquired Robert Stephenson and Hawthorn Limited.

In 1947, a vee-form version of the established ‘K’ range of engines was produced at the Dick Kerr Works of English Electric at Preston. In its original form the in-line, naturally aspirated ‘K’ engine featured a two-valve cylinder head. Bowing to the demands of higher power at increased speeds the revised ‘K’ (or RK) with a four valve head was introduced. Vee version naturally aspirated engines were then made available to give a range of 4, 6 & 8 in-line and 8, 12 & 16 vee engines.

Supercharging the engines was the next phase of development to produce the SRK/SV range and with the introduction of charge air cooling the range was extended to CSRK/CSV.

The first main line diesel electric locomotive for British Rail, No 10000, was handed over by the Vulcan Foundry, in 1947. The locomotive, which was powered by a sixteen-cylinder CSVT engine producing 1600 b.h.p. at 750 r/min., signified the start of a new era which was to see the gradual replacement of the steam locomotive by other and more efficient forms of motive power.

In 1948 an entirely new section of the works was opened to deal with the production of mechanical parts for electric locomotives and the extension included a separate erecting shop, paint shop and fabricating shop.

From 1948 onwards, the Company was in close collaboration with the English Electric Company regarding the manufacture of mechanical parts for diesel-electric locomotives, in addition to the steam locomotives being produced.

Export activity

1949 also saw the first main-line diesel-electric locomotive to operate in Egypt built in the works, and this was fitted with an English Electric 16CSVT engine producing 1520 b.h.p. In 1950 Vulcan Foundry co-operated with English Electric in the design, manufacture and building of the mechanical parts and erecting fifteen 3000 b.h.p. Co-Co locomotives for the Santos-Jundiai Railway, Brazil.

Through progressive development and design work the MkII diesel engine was introduced in 1951. Continued research and development established what additional power could be achieved without exceeding the thermal and mechanical stress limitations that were imposed by the existing design. The main objective of the development programme was to increase mean effective pressure, with operation at higher speeds, using the same cylinder dimensions and the answer was improved turbocharging and charge air cooling, giving increased air throughput together with increased fuelling. The first of the improved engines, a 6SRKT in-line rated at 125 b.h.p. per cylinder, went to the New Zealand Railways.

In 1951 the first of thirty-two 660 b.h.p., Bo-Bo diesel electric locomotives that were constructed for the Tasmanian Government Railways left the works; Vulcan Foundry had designed and built the mechanical parts and erected the first twenty locomotives. One of these was exhibited at the South Bank Exhibition of the Festival of Britain in London during the year.

The first of sixty 3600 b.h.p. double bogie Co-Co type electric locomotives was completed in 1952, this was for the Spanish National Railways and at this time was the most powerful locomotive to be built in the United Kingdom. Together with the development of the RK range of diesels, English Electric also produced dual fuel versions in naturally aspirated and turbocharged forms. Additionally, English Electric produced a range of diesel and dual duel engines in a four stroke ‘L’ series (15" bore x 20" stroke) which were built at Rugby.

In Queen Elizabeth II’s Coronation year, 1953, Mount Everest was climbed for the first time and ten Co-Co type 1500 b.h.p. diesel-electric locomotives were manufactured and shipped to the Queensland Government Railways. A twelve cylinder SVT rated at 1295 b.h.p powered each of the locomotives. The following year saw thirteen type A1A-A1A, 500 b.h.p. diesel-electric locomotives complete for the Rede Ferroviaria do Nordesee (Brazil); these were powered by an eight-cylinder SRKT in-line engine producing 874 b.h.p.

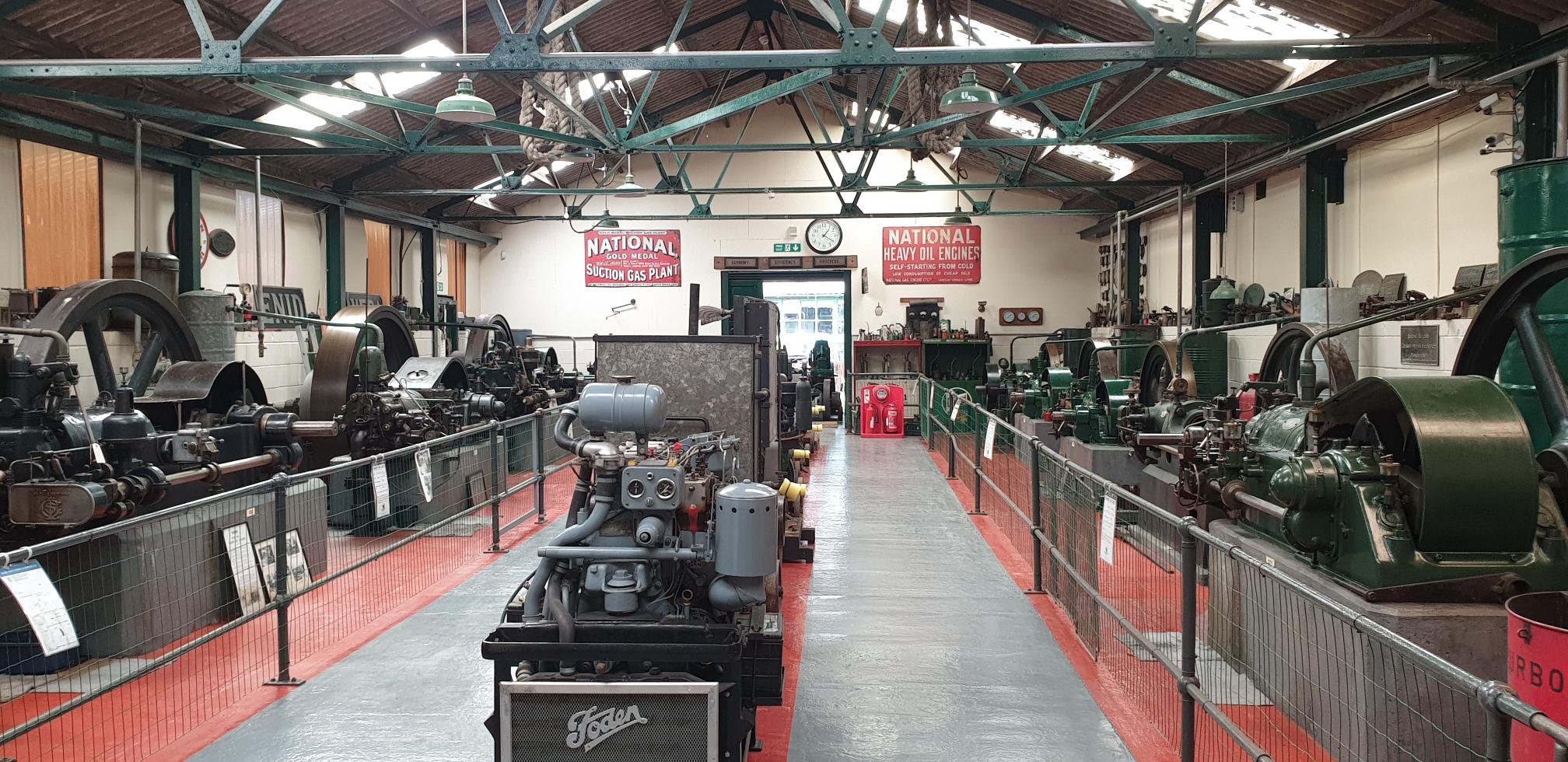

During 1954/5 the Company built seven 3600 b.h.p. Co-Co type general-purpose electric locomotives for the Indian Central Railways to be used for hauling passengers and freight. Also twenty-five Vulcan-Dury diesel-mechanical type locomotives were despatched to the New Zealand Government. Each was powered by a National Gas & Oil Co engine producing 260 b.h.p. at 1250 r/min.

Into English Electric

On March 17th , 1955, the Vulcan Foundry, together with its associated company, Robert Stephenson and Hawthorns Limited of Newcastle upon Tyne. Became full members of the English Electric Group of Companies. In addition to the production of electric and diesel-electric locomotives, the scope of Vulcans activities was increased to include the manufacture of diesel engines suitable for rail traction, marine and industrial applications.

The Renown Deltic

Alone among the diesel locomotive classes running on British Railways, the double-ended Co-Co Deltics were subject to much running-in before taking up full service. This was a consequence of several years-operational experience – over 400,000 miles (644,000kM) – by the prototype Deltic from its construction in 1955 until its demise in 1961. The twenty-two production Deltics, all built at Vulcan Foundry, were delivered from March 1961 to March 1962 and were run-in gradually before being introduced to a full timetable.

The eighteen-cylinder model D18-25 Deltic engine was rated at 1650 b.h.p. at 1500 r/min., giving 3300 b.h.p. output per locomotive and had three banks of six cylinders arranged in the form of an equilateral triangle, with a crankcase linking the cylinders.

Increased diesel power activity

The first of ninety-eight diesel electric multiple trains entered into service in 1957, a four-cylinder SRKT engine producing 600 b.h.p powered each of these. In the same year the first diesel-electric locomotive to be produced for the British Rail modernisation scheme entered service. This was a Type 1 mixed-freight locomotive, subsequently two hundred and twenty eight were built at Vulcan, each powered by an eight cylinder SVT engine producing 1000 b.h.p.

Obtain a good map of Canada and trace the Yukon River northwest from Dawson City to the Alaska border to a tributary named the Fourty Mile River, just west lies Clinton Creek, where in winter the temperature can drop to minus 70OF. The sole reason for the existence of Clinton Creek was the asbestos deposits mined by the Cassiar Asbestos Co. Ltd. Townsite, the homes of the 400 plus community, and the mine relied on five Ruston, nine cylinder ATC powered generating sets for all the electrical power. The units were supplied in 1957 and were directly coupled to alternators delivering 1400 kWe.

D3Also supplied in 1957 were three 8RKD dual fuel alternator sets, each developing 440 b.h.p. for supplying power to the works and workshops of the Middle Lee regional Purification Works. Each generator was coupled to air compressors via a speed reduction gearbox. Also installed at the site were three six cylinder RKD dual fuel engines driving water pumps dealing with storm water.

In 1960, the first Class 37 locomotive to be built was handed over to British Rail. In the following fives years, Vulcan Foundry and its sister company Robert Stephenson & Hawthorns built a total of 309 such locomotives for British Rail. All were powered by a twelve-cylinder CSVT diesel engine producing 1750 b.h.p. and many of these locomotives are still running today.

In 1962 Vulcan Foundry became the Vulcan Works of the English Electric Company Ltd. and the variety of work was increased to include diesel engines for rail traction, marine and industrial applications.

Production of the RK/V range with its design team was gradually transferred from the Dick Kerr Works at Preston.

Development, research and new engine design was moved from Rugby and the office of Brownsover Hall ~ an establishment formerly used by Frank Whittle for jet engine design.

Production of the ‘L’ series ceased.

The new design team introduced the four stroke ‘C’ engine (17.25" bore x 21" stroke). These were the largest engines to be built at Vulcan and a few were made in 6 & 8 in-line and 12 vee. At 428 r/min the turbocharged, charge cooled engine produced 530 b.h.p. per cyl., the engine took the name of Vulcan.

During this year the projected forecasted demand for locomotives fell well below the workshop capacity and the closure of the former works of Robert Stephenson & Hawthorn took place during 1963.

On the 7th September 1963, HMAS Moresby was launched at Newcastle State Dockyard, New South Wales, Australia. She was the first ship in the Royal Australian Navy designed specifically to perform the hydrographic survey role and since commissioning has surveyed throughout Australia and Papa New Guinea territorial waters. Using three Ruston main engines in a twin-screw diesel-electric propulsion system, by 1992 it had achieved the distinction of sailing one million nautical miles, the first RAN vessel to do so.

By May 1964, 1173 diesel and electric locomotives had been built and despatched from the works and in 1965 a Vulcan built twelve-cylinder CSVT engine became the two-thousandth English Electric diesel engine to be delivered to British Rail. This was installed in a Vulcan built standard Type 3, 1750 b.h.p., diesel-electric locomotive.

The affairs of Ruston and Hornsby took a dramatic turn when they were taken over by the GEC Group in November 1966. This caused the complete break up of the Lincoln factory. The large diesels joined with the Vulcan Works at Newton-le-Willows to become Ruston Diesels Ltd. The diesel business at Lincoln gradually declined over the next seven years, finally ending with the closure of the Research Centre.

The engine ranges introduced at Newton were the ‘AT’ (6, 8, 9, 12 and 16 cylinder versions) the ‘APC’ and the ‘AO’. The merged company was Ruston, Paxman Diesels Ltd. later to become Ruston Diesels Ltd.

A fleet of forty-three electric-diesel locomotives, built at Vulcan Works for the Southern Region of British Railways, entered service on 10th July 1967. In normal operation on electrified lines the locomotive acted as 1600 b.h.p. electric unit and was diesel powered on non-electrified lines. These Amphibian locomotives were used mainly on freight trains.

In 1968 the RK3 was introduced as a six-cylinder in-line and 12 and 16-cylinder vee-form producing 270 b.h.p. per cylinder.

The Ruston AO two stroke turbocharged and intercooled engine was introduced in 1968 to bring a new standard of design criteria to shipowners and naval architects. The range was available in 6, 8 and 9-cylinder in-line and 12 and 16 cylinder vee-form units producing from 3000 to 8850 b.h.p.

The first engines went into service in July 1968 and whilst the first engines to be produced were four, nine cylinder versions for the British Rail ferry St. George, the first engines to enter service were two nine cylinder in-line engines fitted into Welsh City.

At Vulcan Foundry the end of another era occurred in 1970 when continuous locomotive production came to an end, the last main line locomotive was supplied to Ghana Railways and Ports. The same year also saw Ruston Paxman Diesels Limited formed as a management company within GEC and in the spring of that year they had taken over the bulk of the Vulcan site.

Next chapter: After locomotive production